Mon – Fri 9:00 am – 6:00 pm India time zone

Mon – Fri 9:00 am – 6:00 pm India time zone

End-to-end solution

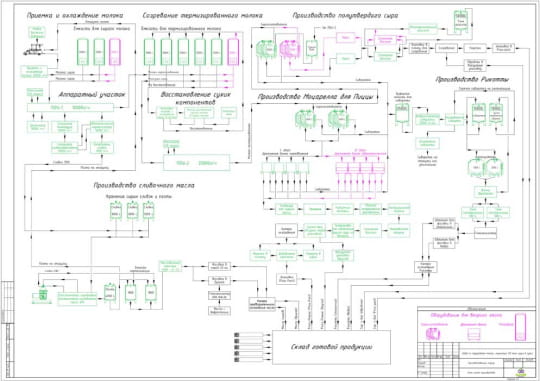

Individual design of dairy production with a volume of processing up to 500 tons of milk per day.

A full package of documentation is provided.

End-to-end solutions for your Business

Any complexity documents preparation in 2.5 months

24/7 service

A well-established logistics system

Allows you to see the structure of your future production. Preparation time: 2 - 2.5 months.

1

step

2

step

3

step

4

step

We will develop design and working documentation, taking into account the current situation. Achieve your goals with detailed analytics.

We take into account current equipment

Optimization and cost reduction expertise

Complete set of additional equipment

Reaching planned capacity

Subsequent development and support

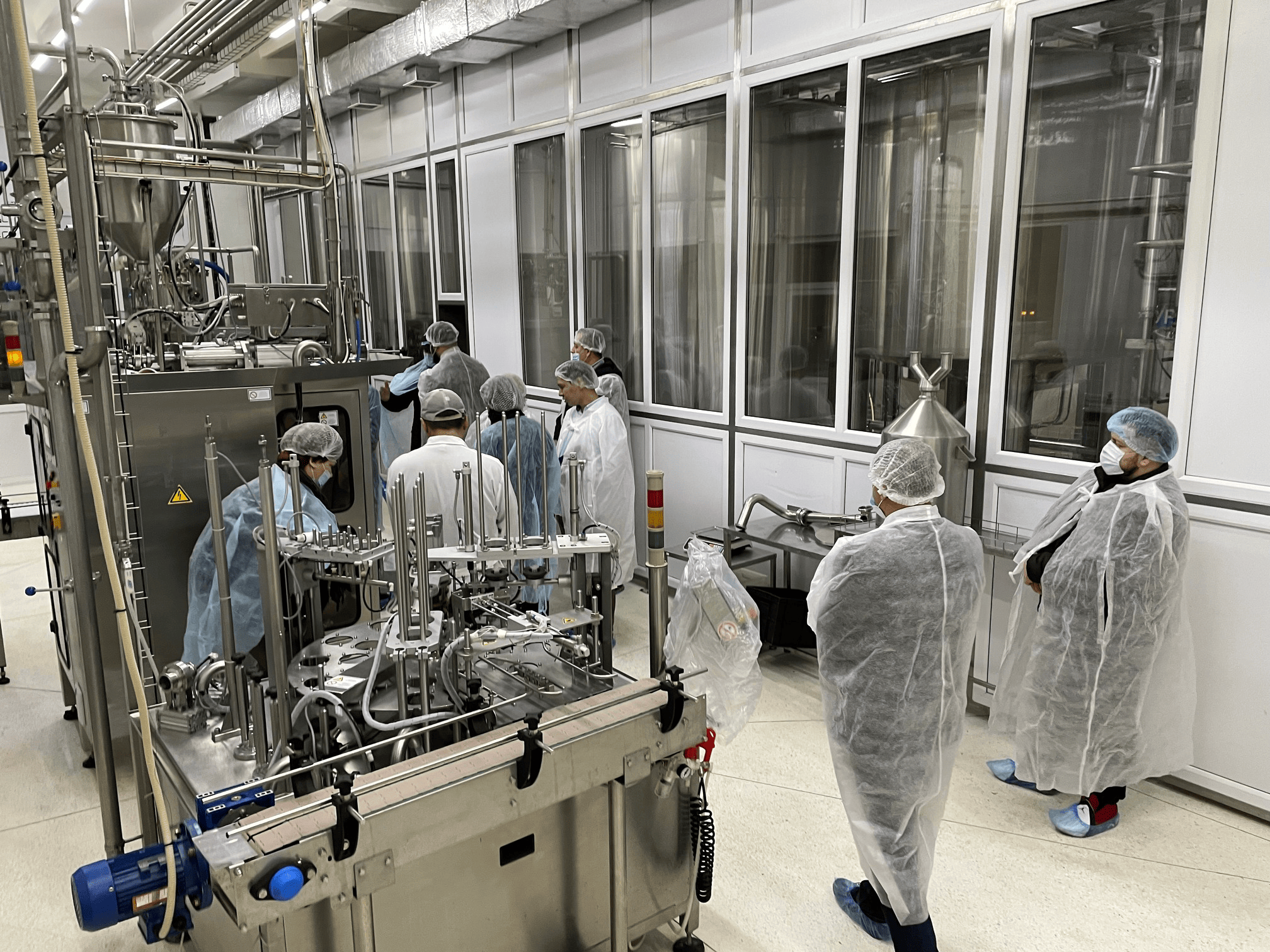

European assembly efficient and energy saving equipment

We prepare design and executive documentation within 2,5 months

Leave a request for a commercial offer

We are constantly improving our competencies, adopting European experience and improving the component base. In cooperation with European partners, we complete tasks on production equipping as well as modernization. Designing is based on highly efficient equipment, components and technologies.